Industrial

Fundamentals

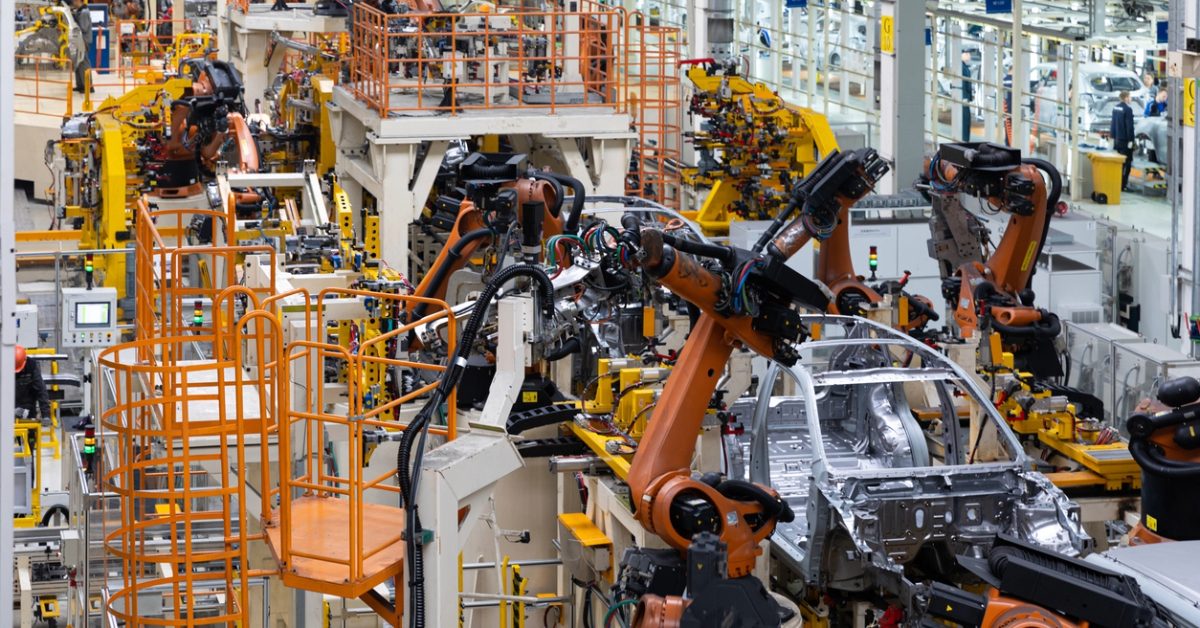

Understanding the Importance of Preventative Maintenance in Industrial Settings

Read the Story

Application Story

Methane Leak Detection: How EPA Changes to NSPS OOOOb and EG OOOOc Impact OGI Inspection Regulations and Guidelines

Read the Story

Use Case Scenario