Your Trusted Partner for ITAR-Free Infrared Camera Modules, Lenses, & Decision Support

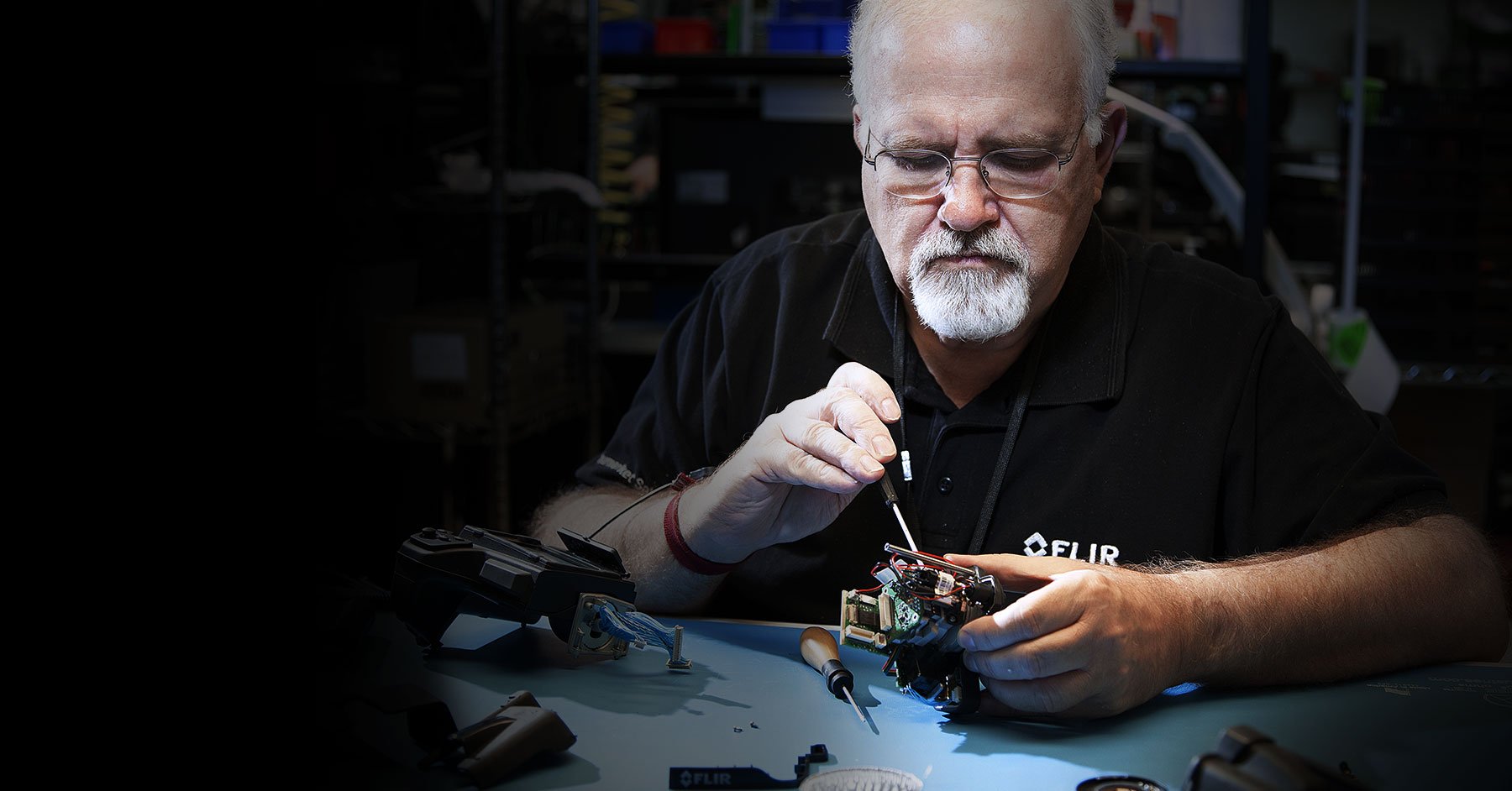

Low-Risk

Supplier

For more than 40 years, Teledyne FLIR has met production-scale delivery with the highest performance standards.

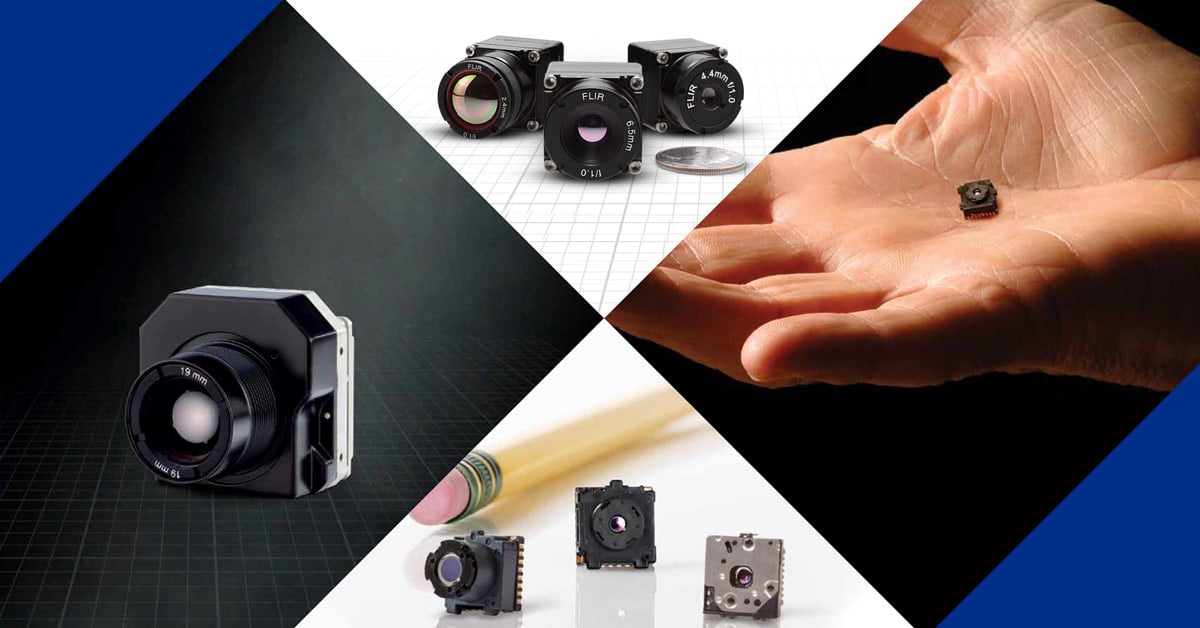

SWaP-Optimized

for any Application

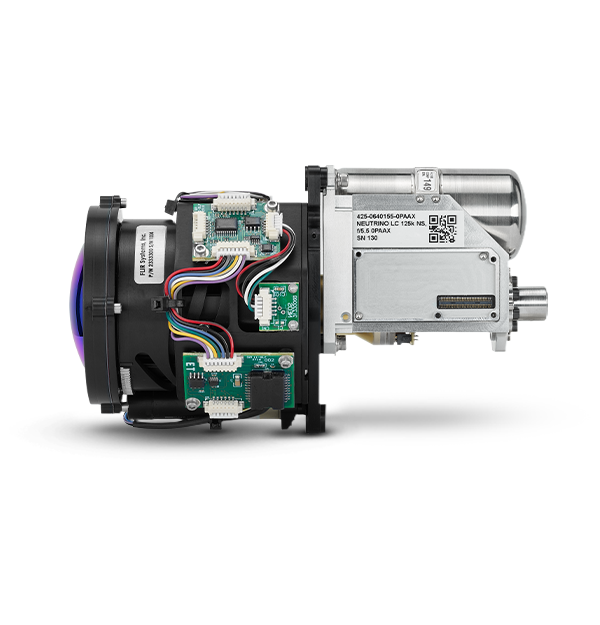

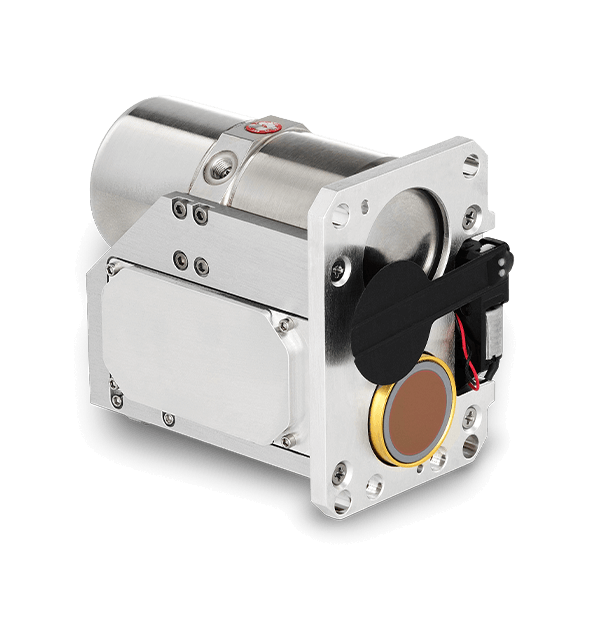

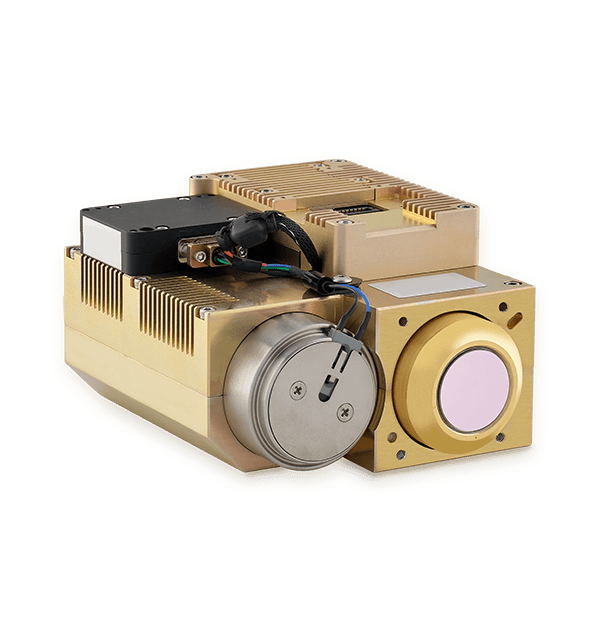

Excel with SWaP-optimized MWIR and LWIR camera modules with factory-integrated lenses, industry-standard interfaces, and intelligence at the edge.

Seamless

Development

Simplify development with an ecosystem of infrared imaging technologies, AI-powered thermal perception, and world-class technical support.

- Airborne and Ground Intelligence Reconnaissance & Surveillance (ISR)

- Tracking and Targeting

- Remote Weapon Station

- Light Armored Vehicles (LAV)

- Soldier Systems

- Military & Defense UAS

- Border Surveillance

- Perimeter Security

- Search & Rescue

- Navigation

- Commercial Drones (sUAS)

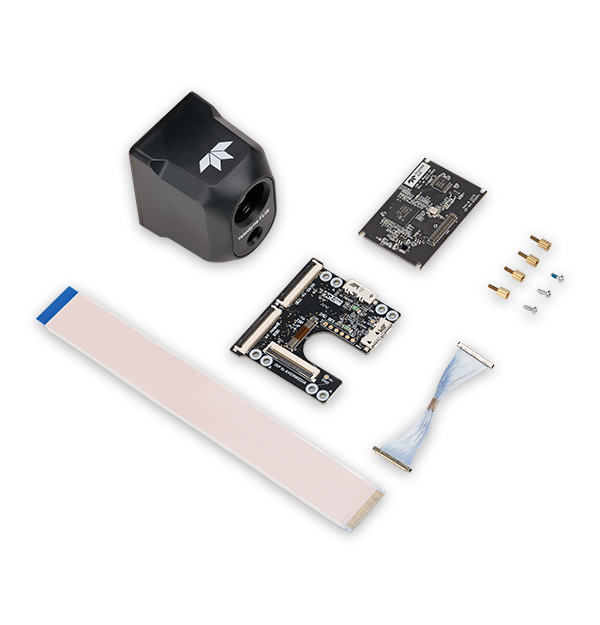

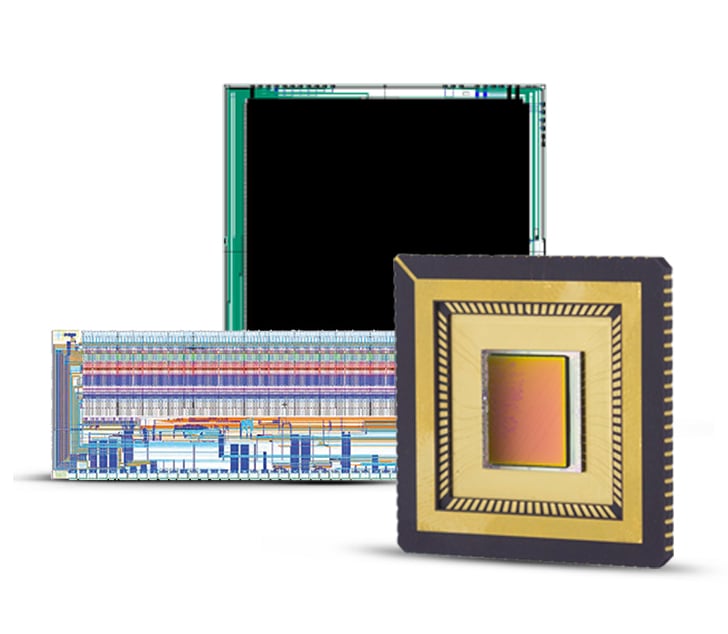

Uncooled LWIR Camera Cores & Sensors

Boson®+ CZ 14-75

High Performance, Uncooled, Longwave Infrared (LWIR) OEM Thermal Camera Module

View ProductCooled MWIR Camera Cores & Sensors

Continuous Zoom Infrared Optics

Boson®+ CZ 14-75

High Performance, Uncooled, Longwave Infrared (LWIR) OEM Thermal Camera Module

View Product

One Provider for Infrared Imaging and Intelligence

Join our mailing list!

Learn about new product announcements, free software / hardware tools, and articles written by OEM integration experts to keep you at the top of the product innovation game.