USDOT Recognition System Helps Keep America’s Roads Safe

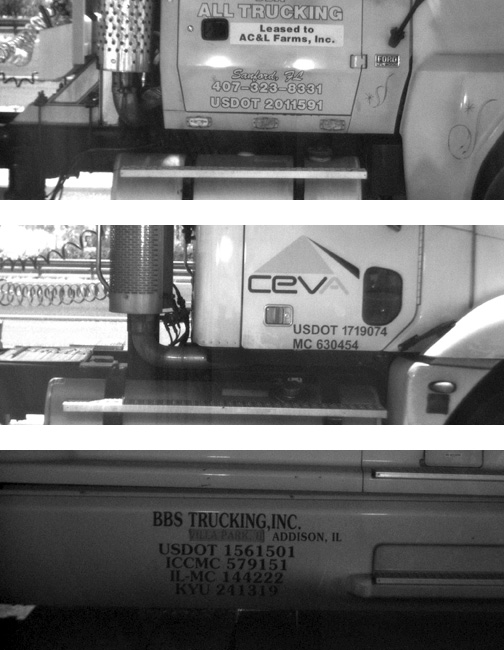

To track their safety records. the U.S. federal government issues USDOT numbers to all commercial transportation companies involved in interstate commerce. Their number is printed on the side of every truck, usually on the door.

Truck weigh and inspection stations are ideal locations to identify operators with safety violations. Currently at many stations, state DOT workers rely on computer terminals to manually look up a carrier's safety records using the USDOT number. Unfortunately, this only occurs during random checks or when the truck has violated weight or other restrictions.

Safety enforcement can be significantly increased by implementing an imaging system that automatically reads the USDOT number from every single truck, day or night, and without requiring the truck to stop or even slow down.

TDS USDOT Reader

In response to this need, Transport Data Systems (TDS) has developed a complete solution for capturing and decoding USDOT numbers located on the side of a truck. The system is designed to work 24 hours a day, in any outdoor lighting condition, capturing vehicles moving at very high speeds. Once the image is captured, the USDOT Reader extracts the USDOT number and cross references this number against various federal agency databases. Vehicles in question are immediately identified. The results can be accessed via a browser and are stored for future reference or report generation.

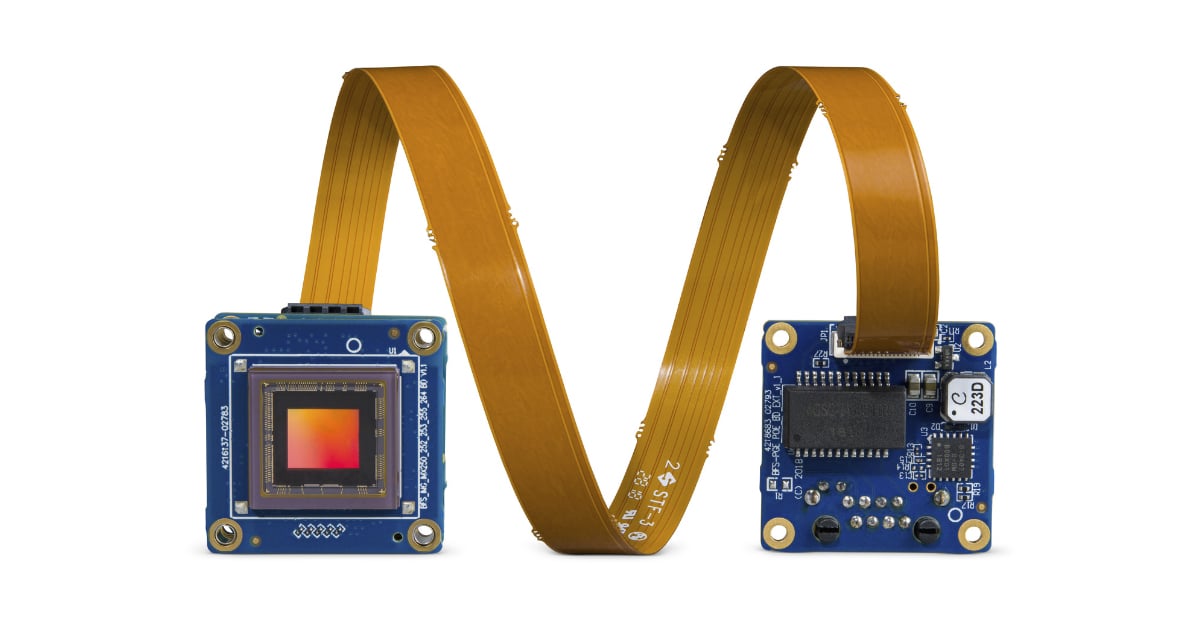

Choosing the right camera

The challenge for this kind of image capture is to choose a camera that offers a combination of:

- High sensitivity to ensure short exposure time to eliminate motion blur cause by vehicles speeds over 60 MPH;

- A large field of view is required to ensure the entire USDOT number is contained in a single frame;

- High resolution to ensure accurate and reliable OCR (optical character recognition) reading

- High dynamic range to distinguish image features during all weather conditions.

There were also other requirements. For example, TDS prefers cameras that support an industry standard interface such as IEEE1394b. In addition to high data bandwidth, IEEE1394b provides reliable third party software compatibility and support for Linux.

TDS explored a number of camera options before choosing FLIR's Grasshopper 5MP camera model GRAS-50S5M. As TDS President, Tom Hasselbring explains, "We looked at a variety of cameras on the market, but for this application, the Grasshopper's combination of flexible control, image quality, cost-effectiveness, and 1394-compatibility won out."

An example of the Grasshopper's flexibility is the ability to use region of interest to reduce the field of view's vertical resolution so that only relevant data, such as the side of the truck, is captured. The remaining parts of the original image such as the sky or wheels are not transmitted. This reduces the size of each image frame, processing requirements, required storage capacity while allowing a higher camera frame rate.

System Setup: From Trigger to Processing

Each installation varies depending on the lane geometry of the inspection station. In a recent DOT installation in Montana, trucks pass through a series of sensors along the access road as they approach the inspection station. Signals from the sensors detect the presence and location of each passing vehicle. These signals are connected to the USDOT Reader which in turn triggers the Grasshopper camera. The camera's optically isolated hardware trigger output is used to strobe the TDS' custom-made infrared (IR) LED illuminators. Using pulse-width modulation and synchronizing image capture with the strobe provides optimal illumination for sharp and crisp images needed for accurate OCR reading. The Grasshopper camera was mounted in an outdoor enclosure perpendicular to an automated weigh station and connected to a road-side mounted PC running TDS image-processing software.

A pair of images is captured at a shutter speed of 1/100th of a second with a small delay between acquisitions. The delay time is based on the speed of the vehicle. The two images capture the entire side of the towing vehicle. Both images are processed by a roadside Linux based multi-core PC running TDS's proprietary OCR algorithm which determines the vehicle's USDOT number.

Mr. Hasselbring continues, "We've worked with FLIR for many years. What keeps us coming back is the quality of their products and their technical support team which is unparalleled in the industry."

What's next?

With the proliferation of weigh-in-motion stations where trucks do not need to stop or slow down to be weighed, demand for systems like TDS' USDOT system will only grow in the march towards systematic efficiency.