Infrared Camera Calibration

FLIR cameras are designed and factory calibrated for accurate temperature measurements and thermal imaging. When maintained with FLIR’s annual calibration services, they will be highly reliable in spotting thermal anomalies and other temperature phenomena. Without proper maintenance and calibration, accurate measurements nor image quality cannot be assured.

The calibration of each FLIR camera model is unique. Therefore, FLIR’s Aftermarket Organization is uniquely qualified to keep your camera in peak operating condition for optimum reliability and accuracy in data collection. This division is certified according to ISO 9001:2008 (Nov. 2010) or AS9100.

12-Point Inspection & Calibration Program

FLIR's exclusive 12-Point Inspection & Calibration program uses temperature references that are calibrated annually and traceable to the SP Technical Research Institute of Sweden, and the National Institute of Standards and Technology (NIST). The program includes the following steps:

FLIR 12-Point Inspection & Calibration Program:

- Perform a complete operational check

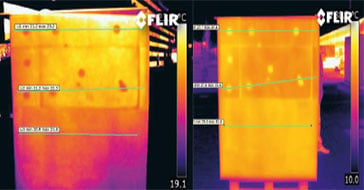

- Image calibration and camera alignment, when applicable

- Verify all internal cable and PCB connections

- Upgrade internal camera software to latest revisions

- Perform minor repairs

- Verify and/or calibrate IR image as needed each temperature range for image uniformity

- Verify ambient temperature compensation as needed

- Re-calibration to ensure it meets factory specification

- Perform quality approved acceptance test procedure

- Provide certificate of conformance

- Provide calibration certificate (optional, extended calibration certificate with measured values)

- Clean optics; viewfinder cleaned when applicable

*Does not include parts or labor required to meet calibration standards, nor additional lens/filter calibrations.