Infrared Thermometers 101

For technicians who rely on temperature to check the condition of equipment, IR thermometers are indispensable. Is electrical equipment overloaded and overheating? Or is the current room temperature a result of a failed AC system? Is the air coming out of a vent too hot or too cold? IR thermometers, also called IR guns, spot thermometers, or spot pyrometers, can make it easy to scan equipment and sites for abnormalities that need attention.

Certain IR thermometers allow you to document your inspections with video or digital images.

IR thermometers use a temperature sensor that measures heat as infrared radiation. They are gun shaped, with a grip, a trigger, a laser pointer(s) to mark a target, a temperature readout display, and control buttons on the rear. IR thermometers are usually point-and-shoot tools, where clicking the trigger turns on the laser sight.

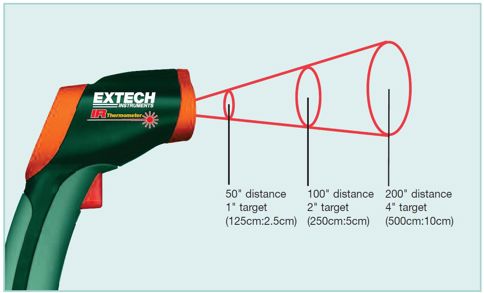

IR thermometers measure the average temperature of a 1-inch (2.5 cm) diameter spot (about the size of a quarter) from a predefined distance. This is the distance-to-spot ratio. With a smaller ratio such as 12:1, a user needs to scan within 12 inches (30.5 cm) from the target for an accurate reading. Others can work from a much farther distance, such as a 50:1 IR thermometer that can accurately measure temperature up to 50 inches (1.3 m) from the target. Some IR thermometers use two laser pointers to illustrate the actual diameter of the spot and make targeting easier.

Some IR thermometers are designed for general-use temperatures up to 630°F (332°C), while others have high temperature ranges nearly reaching 4000°F (2200°C) for jobs such as kiln inspections, foundries, glass manufacturing, and smelting.

To expand their versatility, IR thermometers may also measure ambient temperature. This is useful for jobs where work can only be performed above or below a specified temperature, or if a user wanted to calculate the difference between ambient and surface temperatures. Others come equipped with a thermocouple probe so that contact temperatures can also be taken. These options complement the non-contact reading for better diagnostics and decision-making. For professionals who routinely scan areas looking for abnormal temperatures outside of a specified range, some IR guns can be programmed with high and low alarms that alert users when thresholds are exceeded.

Around the world, job sites that factor temperatures into troubleshooting use IR thermometers. Electrical contractors can use them to scan panels for overheating breakers. HVAC technicians can use them to check temperatures on registers, returns, and vents. Industrial plant maintenance technicians check belts, under-lubricated shafts, and overheating motors prone to failure. Home energy inspectors check for energy leaks around windows and doors. Automotive techs check hose and vent temperatures. Even confectioners can use them to check chocolate temperatures. The list goes on.

Use special high-temperature models for extreme jobs.

Choose an IR thermometer with capabilities matched to your job’s needs. Here’s a checklist of things to look for when selecting an IR thermometer: