Software that Writes Itself: Eigen Innovations Uses FLIR Infrared Cameras to Simplify Automation Solutions

Setting up a machine vision system and making all the different parts work smoothly can be hard work. You need to integrate hardware and software and often multiple cameras will be involved. Eigen Innovations, a specialist in real-time monitoring solutions for many industries, has developed a smart hardware module that makes this integration process much easier. And when Eigen installs this module for its customers, the company likes to work exclusively with FLIR cameras.

Eigen Innovations tries to make factories smarter, by offering solutions that can capture real-time data from the factory floor, apply advanced analytics to it, and automatically improve operating processes. This boosts factory productivity and ensures consistent quality, all while reducing operating costs. Scott Everett is the CTO and co-founder of Eigen Innovations. He started the company in 2012 as a university spin-off.

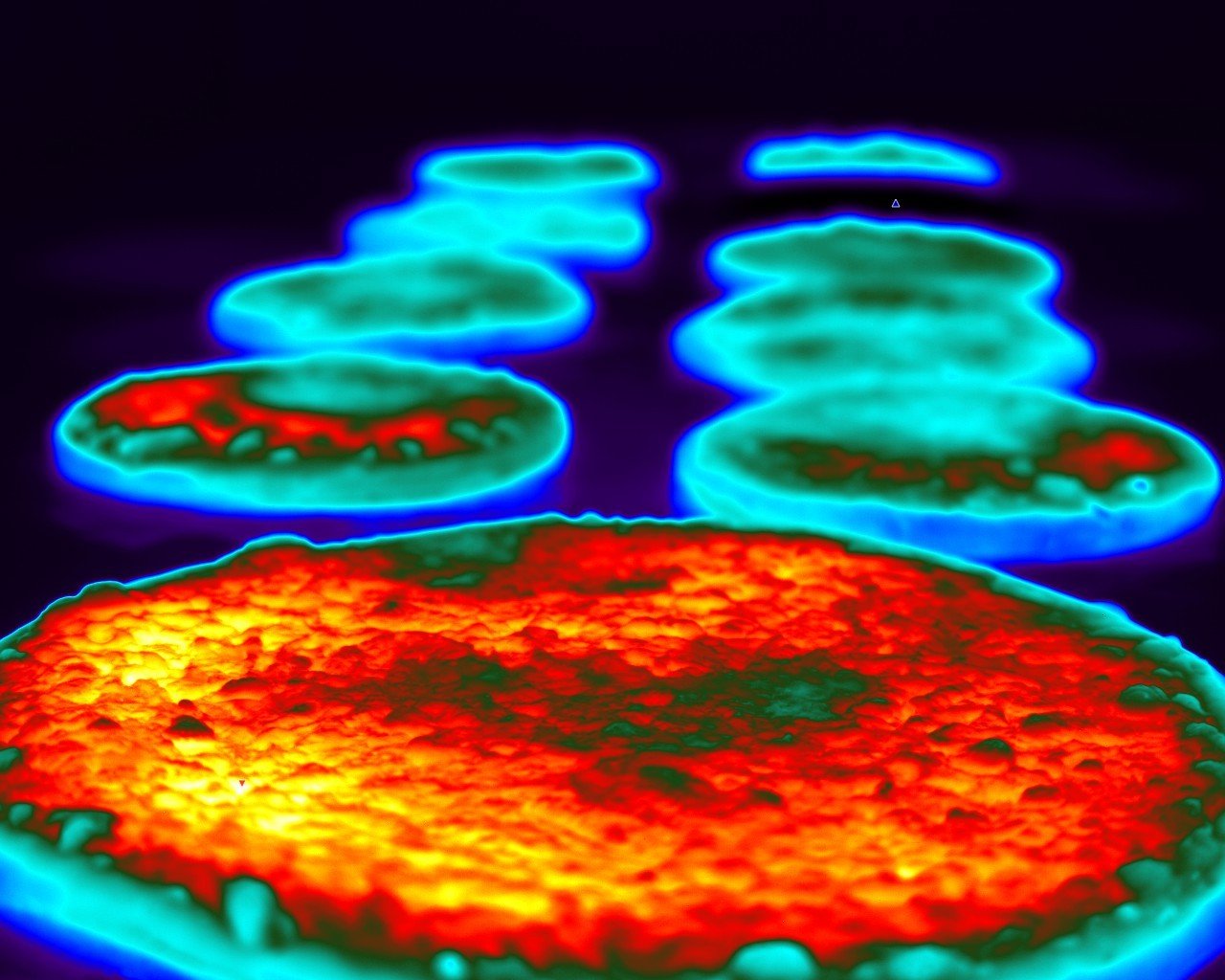

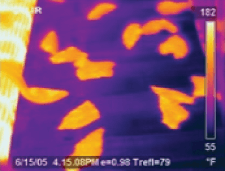

“We started with building software control solutions for manufacturing systems in key markets such as injection molding, where a variety of sensors are used. Looking at the temperature profile of a part coming out of the machine is a good quality check. One of the issues of doing a quality measurement is that your product has to cool down first, which can take a while. With a thermal camera, being a non-contact sensor, you don’t have to wait anymore. You can monitor quality in real time. We discovered thermal imaging from FLIR at a trade show and we quickly realized that a thermal camera is so much more than a camera: it’s an intelligent feedback sensor for real-time processes.”

Cost-effective integration

Building a monitoring and alarming system for fixed mounted automation applications can be a tough and expensive process. Since every application is different, custom software solutions are often needed in addition to the sensor, communications and computing hardware. Eigen’s Smart Module (ESM) eliminates this costly step in the process.

“If we wanted to offer our customers a cost-effective monitoring system, it was clear that we needed to find a way to make the integration of the cameras, hardware and software much easier. That’s why we developed our Eigen Smart Module,” says Scott Everett. “In addition, using FLIR cameras has made our job easier as well. Sales cycles for industrial solutions like ours tend to be very long, but when we can present a thermal image and show our customer what it says about a production process, it can get the ball rolling for us.”

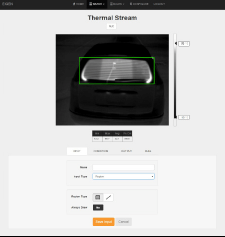

Eigen Smart Module

The Eigen Smart Module is a robust GigE Vision thermal camera module with monitoring and alarming capabilities for fixed mounted automation applications. The module allows for easy configuration of temperature thresholds and enables PLC communications. The Smart Module has been designed to enable rapid deployment of fixed mounted thermal cameras for monitoring and alarming applications, eliminating the need for custom integration. The module communicates with GigE Vision thermal cameras and performs temperature based calculations on designated regions-of-interest.

The Eigen Smart Module is also a self-learning system. It can be used as a standalone solution, but as part of a larger architecture and for more complex processing the module collects training data from the thermal camera, trains the data in the cloud, and pushes it back into the module. In effect, the software writes itself.

The module can be used for a variety of automation applications, including parts manufacturing, pulp and paper, food processing, fire prevention and condition monitoring. And of course, Eigen Innovations is always on the lookout for new applications.

Built around FLIR

The first release of Eigen’s Smart Module is completely geared towards GigE Vision standards and FLIR’s A-Series cameras.

Scott Everett: “It doesn’t take much research to see the expertise which FLIR has built up. If you look at the company’s portfolio and history, it made the most sense to choose FLIR cameras. Apart from that, we have developed a great relationship with FLIR and the company has opened doors for us in the automation market. So it really has been a mutually beneficial relationship.”

“The great thing about thermal imaging cameras is that you can see the complete temperature distribution of an object, not just one temperature point as thermocouples are showing you. This results in a huge amount of data, complemented with other sensor information like pressure, speed or moisture data. Our module combines the information of all of these sensors and tries to make sense of it.”

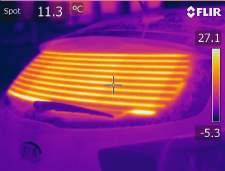

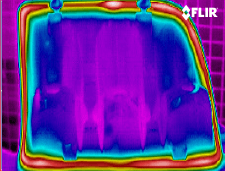

Examples: rear window defogger, pile monitoring

Eigen Innovations has successfully deployed its smart module for an automotive customer. More specifically, the module and FLIR cameras are set up on a car assembly line to detect problems with the rear window defogger. In the assembly line, the defogger is turned on and a FLIR A-Series thermal imaging camera is used to check whether the heater bands are working fine.

“Normally in an automation setup, the parts that need to be controlled have a fixed position. In this case however, you need to wait until the car comes into view. That’s why the algorithms integrated in our module need to determine the position of the car first.”

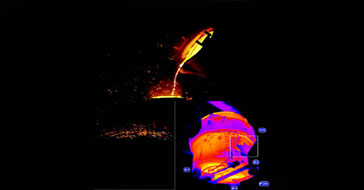

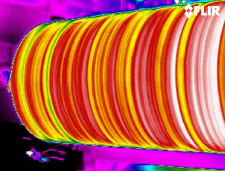

Another example is outdoor monitoring of sulfur piles. In order to prevent self-combustion of sulfur, FLIR cameras are used to look for hot spots indicating a looming fire. Eigen’s Smart Module is specifically useful here for improving the detection performance and to reduce the number of ‘false positives’, e.g. when heat is detected in case of birds flying by. The Eigen Smart Module can train the data to see whether the camera is looking at a bird, a loader truck, or an actual fire.

FLIR A-Series: powerful and cost-effective

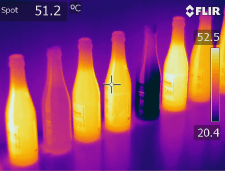

Having installed multiple Smart Modules already, Scott Everett is very happy with its choice for FLIR, more specifically with FLIR’s A-Series cameras. “We are especially fond of the FLIR A65 and its beautiful high-resolution images. It is impressive how something so powerful can be built so small.”

“With the current price level of the FLIR A35 and FLIR A65 for example, you can now easily include three to four cameras in an installation. Even though it is a cost-effective solution, the FLIR A-Series camera can replace a conventional line scanner application. The difference is that a FLIR camera is not only scanning one line, it is presenting a complete image.”

The A-Series cameras use the GigE Vision standard, which allows for fast image transfer using low cost standard cables even over long distances. With GigE Vision, hardware and software from different vendors can interoperate seamlessly over GigE connections.

The A-Series is also very robust and can be used for monitoring applications in harsh environments.

Ready for the Internet of Things

“In our line of work, there is much talk about the industrial internet, or the Internet of Things, where complex machinery is connected with networked sensors and software,” says Scott Everett. “Of course, when you want to use all of this sensor data to its full potential, you need to have qualitative sensors that deliver qualitative data in the first place. In that respect, I believe that FLIR and Eigen Innovations are facing a very exciting and promising future.”