Save Energy Costs and Improve Efficiency

![]()

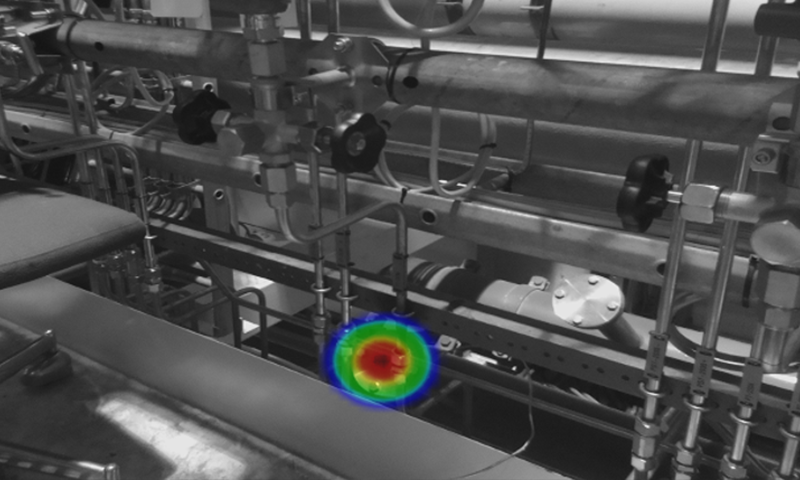

Acoustic Imaging for Pharmaceutical Manufacturing

Compressed air and vacuum system leaks—both prevalent in pharmaceutical manufacturing—can result in significant costs, operational disruptions, and safety risks. In fact, some facilities lose up to 80% of compressed air to these elusive leaks. Detecting them is crucial but often challenging due to their invisibility.

Enter the acoustic imaging camera: a precise, efficient, and user-friendly solution tailored for pharmaceutical plants. FLIR Si-Series cameras are safe, easily-operated devices that can be used with minimal training to identify leaks.

With an acoustic camera you can:

- Proactively Detect Leaks: Reduce energy use and lower operational costs by finding and addressing leaks immediately.

- Avoid Unnecessary Downtime: Use acoustic to inspect critical assets while they're active, minimizing work disruptions.

- Drive Informed Repairs: Get insights from AI-driven analytics on leak magnitude and associated cost implications.

- Integrate Seamlessly: Minimal training required for efficient incorporation into maintenance routines.

Calculate Your Return on Investment

Minimize Gas Losses

If your production process uses gas, then acoustic imaging can detect and report leaks, helping to reduce financial losses and lower the cost of doing business.

Use the Si-Series to detect:

- Carbon dioxide

- Oxygen

- Nitrogen

- and more

The gases used in various production processes represent a significant cost to business, so minimizing these leaks can make an immediate impact to the net profit at the end of the year.

![]()

FLIR Si-Series Acoustic Imaging Cameras for Compressed Air and Vacuum System Leak Detection

Ultrasonic imaging with an acoustic camera is an effective way to identify efficiency loss and potential failures up to 10 times faster than traditional methods—with minimal training.

Core Benefits of Acoustic Imaging:

- Reduced energy usage

- Reduced CO2 and other gas emissions

- Prolong compressor/vacuum pump life

FLIR Si-Series Advantages:

- No training required

- Concise reporting

- Leak quantification

- Background noise filtering

- Accurate measurement of leaks as small as 0.004 l/min from 1 m (3.0 ft)

![]()