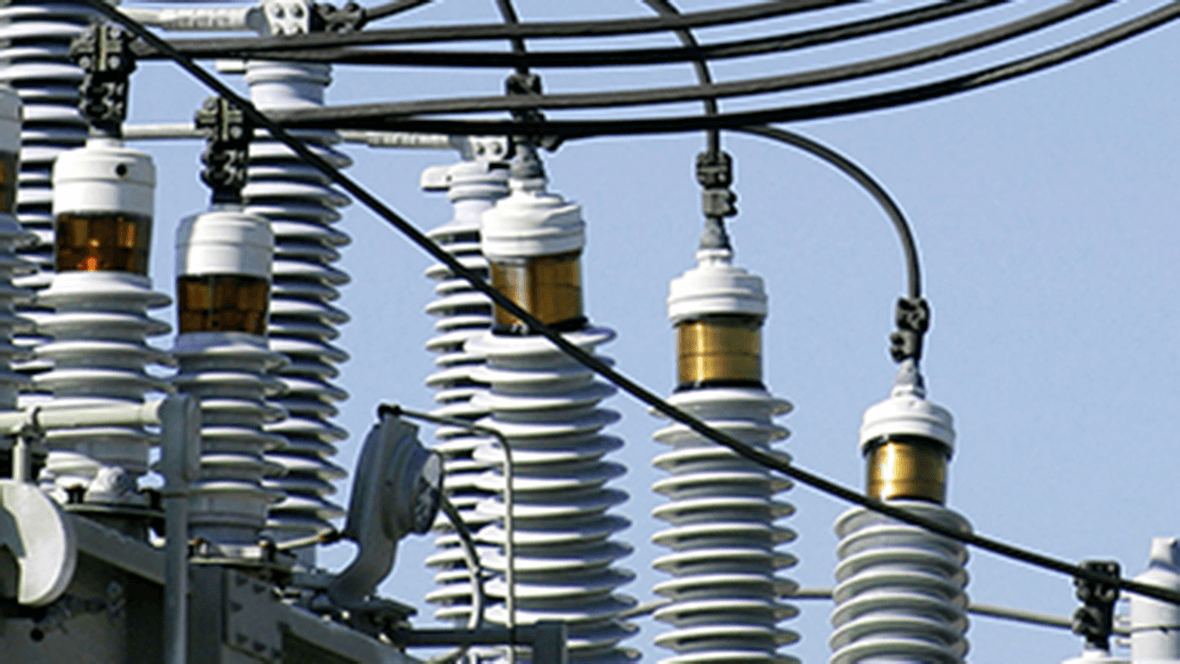

Application Spotlight: Maintain and Inspect Bushings

Prevent Downtime with Thermal Imaging

Bushing failures can cost your company millions of dollars in lost revenue from downtime, repairs, and overtime pay for workers. Through regular inspections, you can detect bushing failures before they occur. Traditional inspection methods, including Micro-ohm tests or power factor measurement, can be labor-intensive and require you to take the system out of service. Incorporating thermal imaging technology into your inspection routine allows you to collect temperature data in real time, pinpoint hot spots on bushings before a failure occurs, and avoid unnecessary downtime.